Souto Moura Design Wood Burning Stove

Souto Moura Design Wood Burning Stove

Couldn't load pickup availability

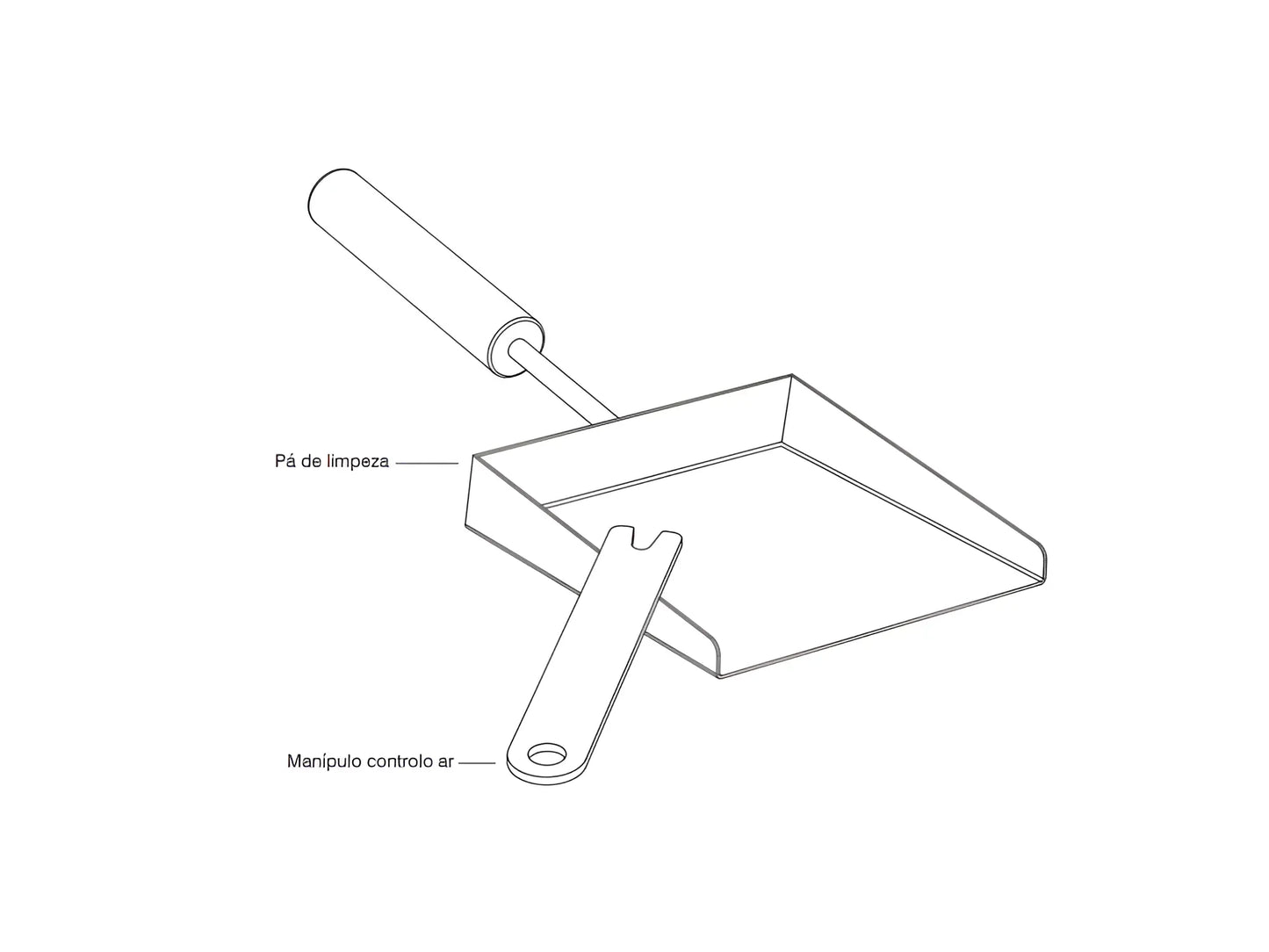

Wood-burning stove designed by renowned architect Eduardo Souto Moura. Composed of a set of steel parts, plus a set of moving parts such as deflectors and vermiculite panels. This stove was manufactured solely and exclusively to burn wood, never with coal or treated wood.

- Intermittent operation heating device

- Wood combustion on a vermiculite base

- Bottom-opening front door, equipped with ceramic glass resistant to 750ºC, which allows you to see the fire, and at the same time, complete protection against sparks

- Combustion air inlet register installed at the top of the door

- The door, hidden when open, retracts completely, using its handle with Takula wood application.

- The glass is silkscreened and has a self-cleaning system

- The leveling feet are made of polished stainless steel.

- Combustion chamber, lined with vermiculite panels with double smoke deflector, allows efficient and economical burning of wood

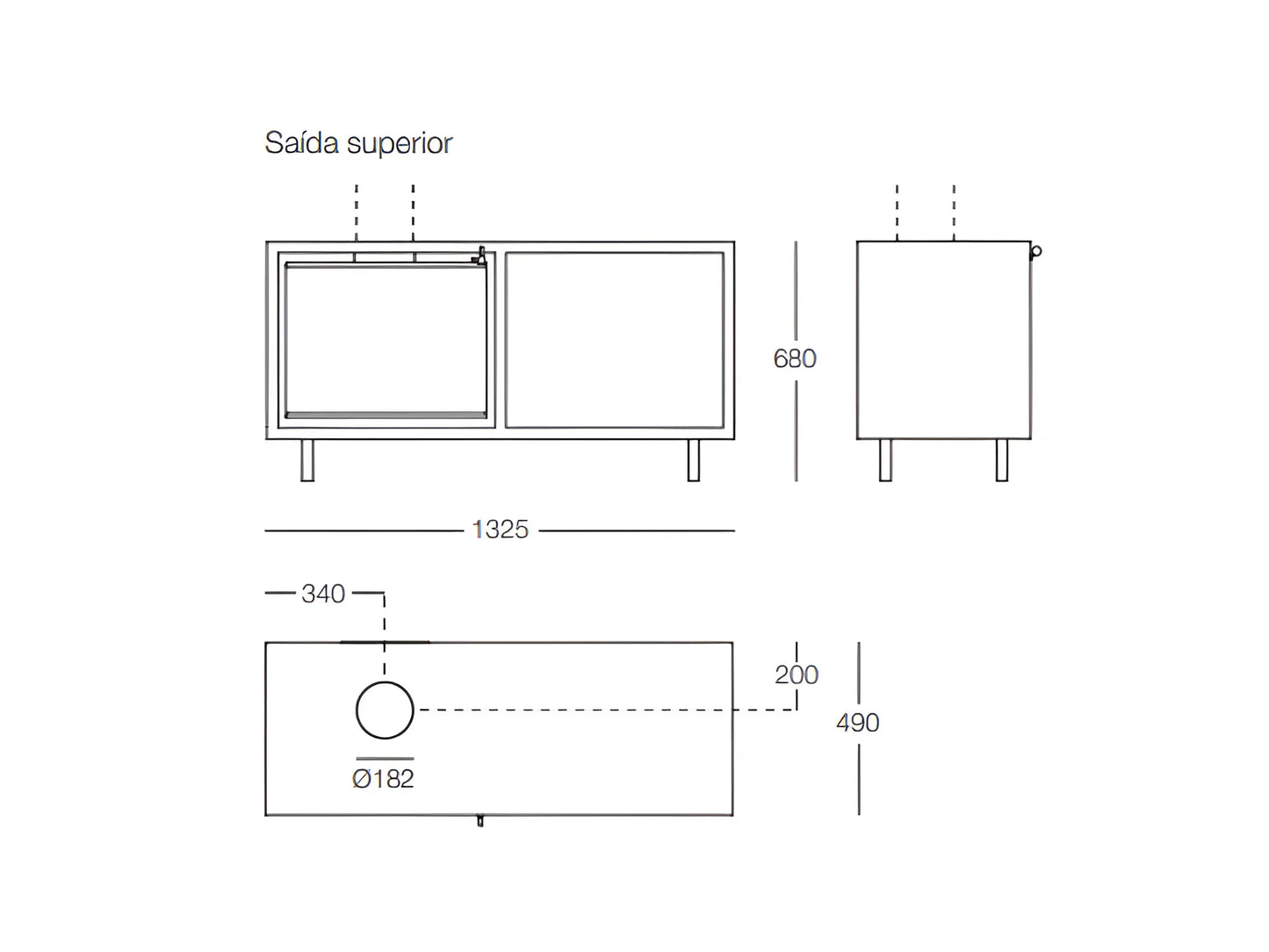

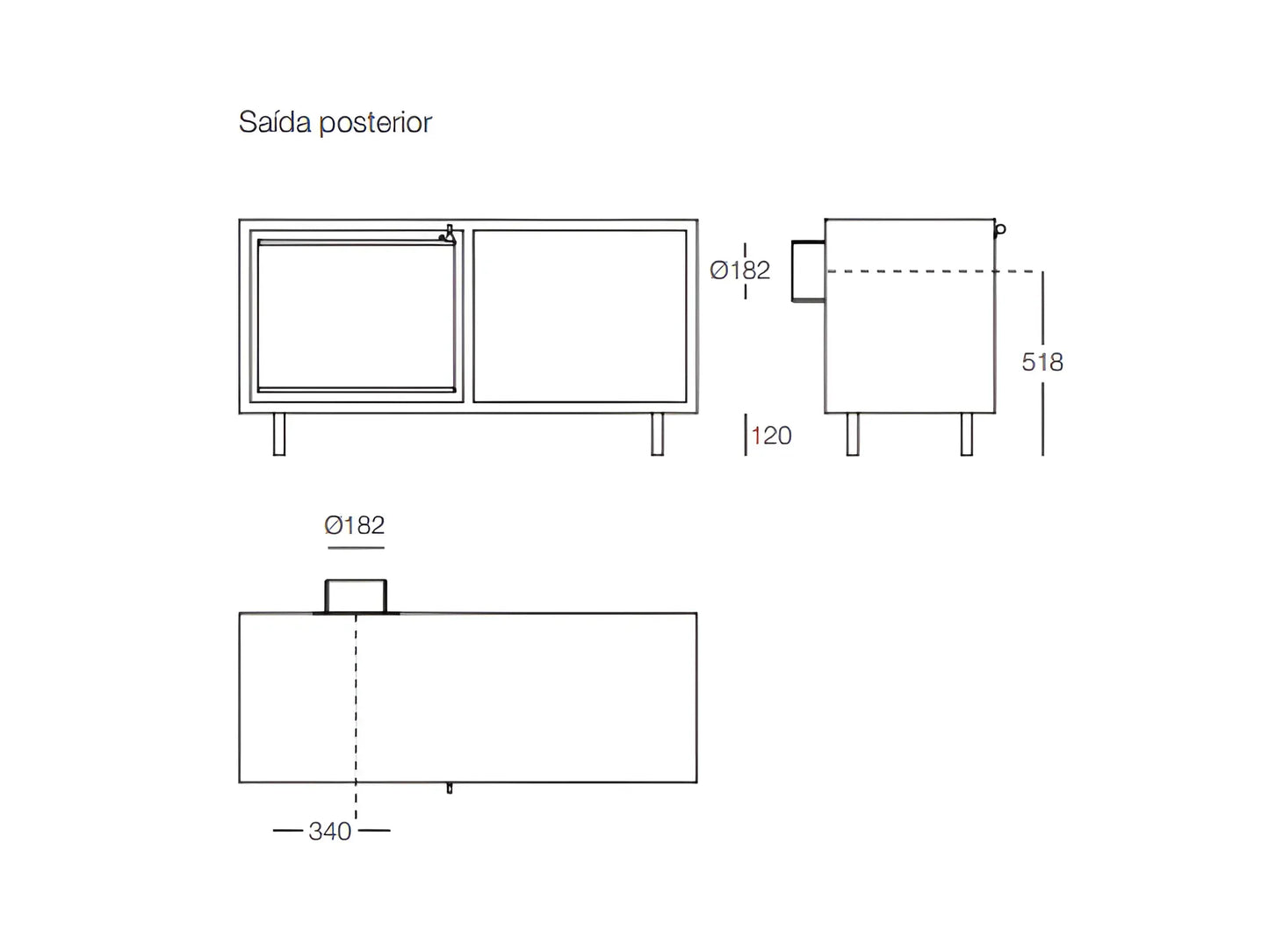

- The chimney is hidden, with a rear smoke outlet, allowing greater discretion of the equipment in the space. It can, as an option, have an upper outlet and be installed in plain sight.

- Made in Portugal

Features of the Fireplace with Firewood

Weight: 185 kg

Chimney diameter: Ø180mm

Rear smoke outlet: Ø182mm

Upper smoke outlet: Ø182mm

Combustion chamber dimensions (wxhxd): 504x300x305mm

Maximum firewood size: 480mm

Firewood consumption: 2.4 kg/h

Thermal output: 7.6 kW (5.5 kW min. - 9.6 kW max.)

Yield: 77% (min.68%-max.79%)

CO concentration at 13% O2: 0.2%

Temperature of combustion products: 308 ºC

Combustion product flow rate: 6.15 g/s

Time between recharges, nominal power: 0.86 h

Area to be heated: 60 m²

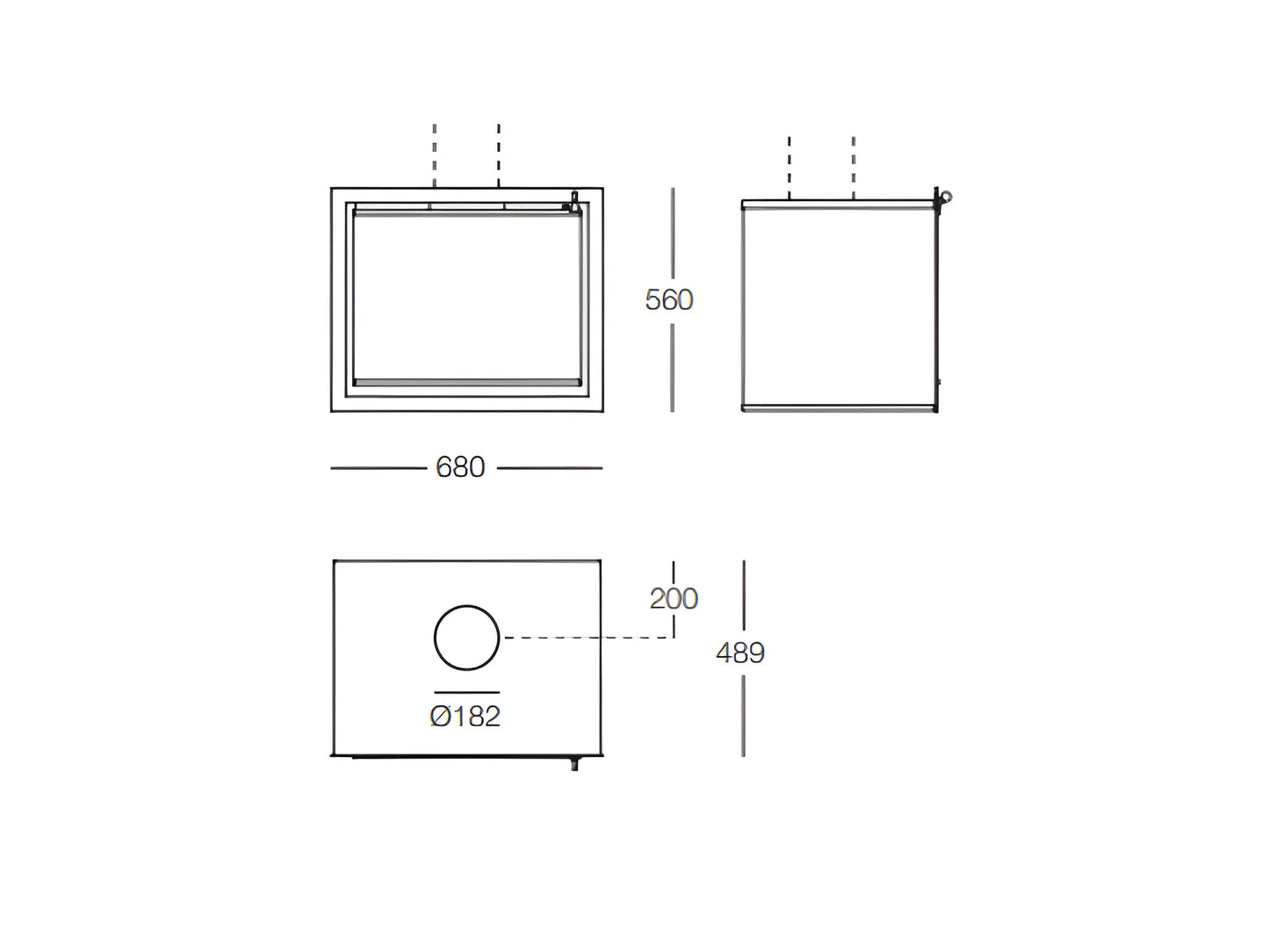

Built-in stove characteristics

Weight: 113 kg

Chimney diameter: Ø180mm

Upper smoke outlet: Ø182mm

Combustion chamber dimensions (wxhxd): 504x300x305mm

Maximum firewood size: 480mm

Firewood consumption: 2.7 kg/h

Thermal output: 7.5 kW (7.2 kW min. - 7.8 kW max.)

Yield: 61% (min.60%-max.62%)

CO concentration at 13% O2: 0.05%

Temperature of combustion products: 347 ºC

Combustion product flow rate: 12.86 g/s

Time between recharges, nominal power: 0.99 h

Area to be heated: 60 m²

Before Installation

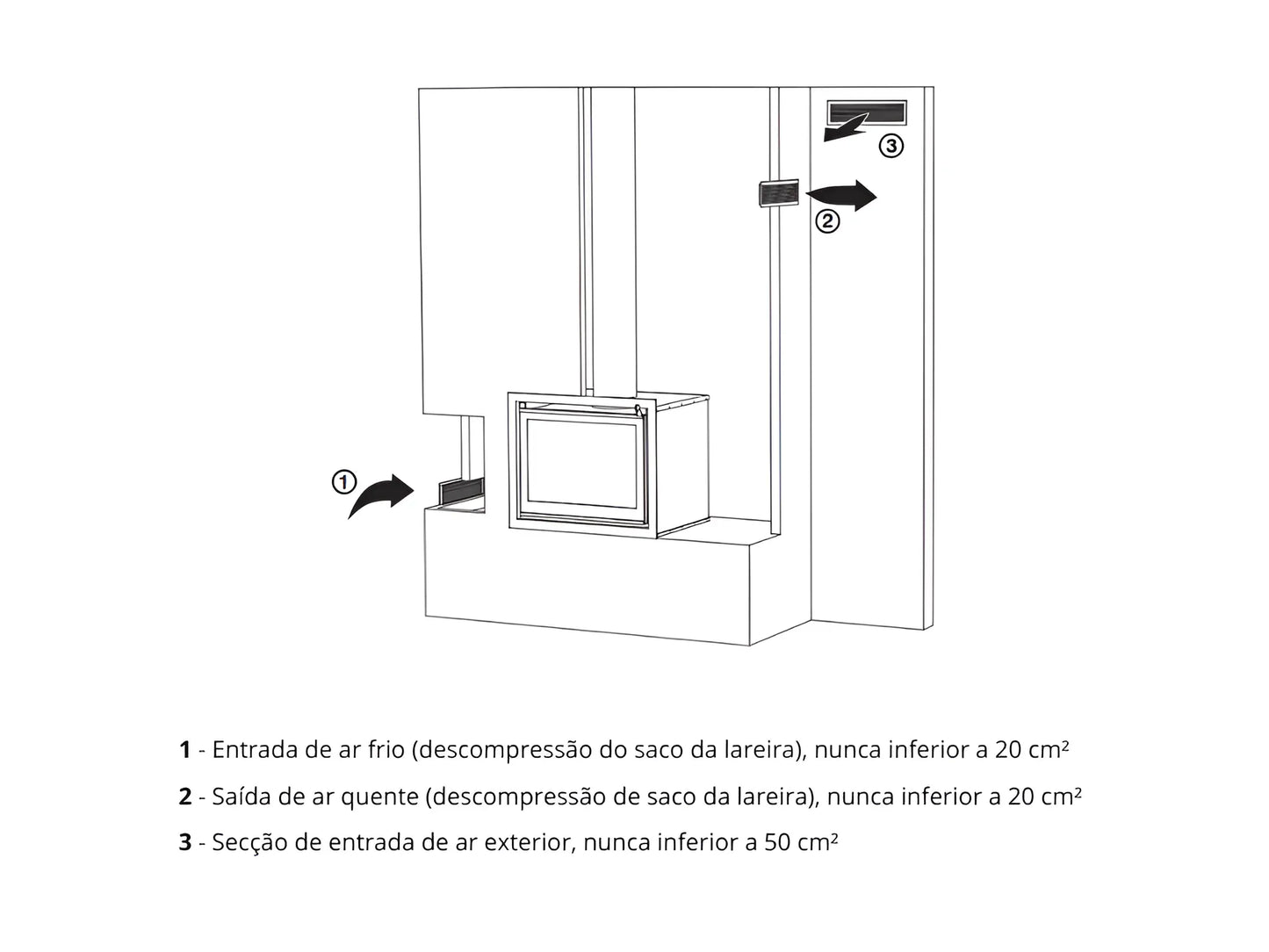

- Check that the place where the stove is to be installed has a sufficient supply of oxygen. Wood combustion consumes oxygen. If the room where the stove is located is airtight or has a controlled ventilation system, clean air must be supplied from outside by installing an additional grille with a cross-section of no less than 50 cm².

- Ensure that the support base is capable of supporting the total weight of the stove.

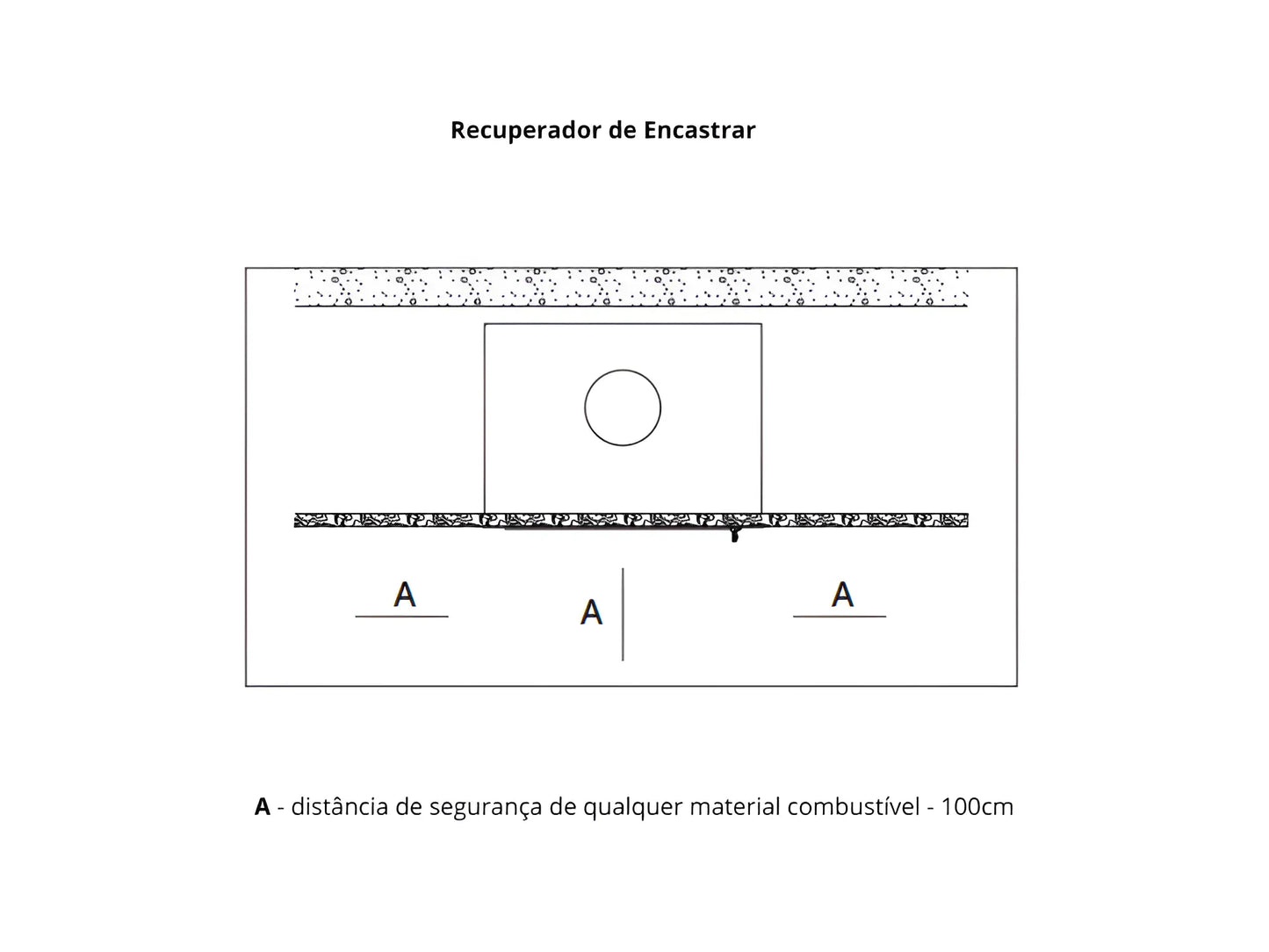

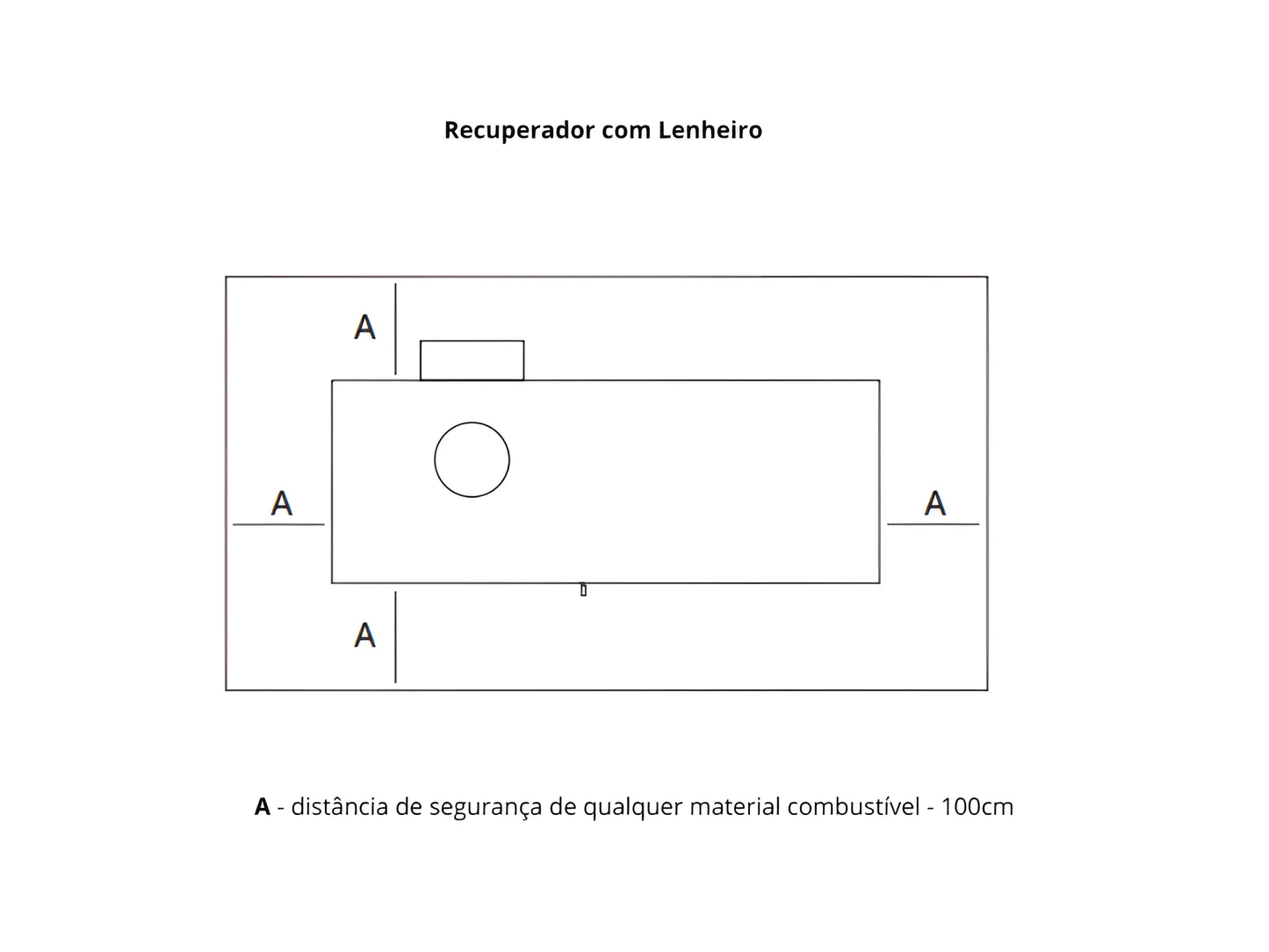

- Ensure that the materials surrounding the equipment are not flammable (paper, plastics, wood, etc.).

- We must take into account the safety distance from any object that could deteriorate due to the effects of heat.

Smoke Duct

If it already exists:

- Check that the construction is in good condition and that, when the device is in operation, there is a differential pressure of 12Pa to ensure good draft.

- The duct must be compatible with the use, especially with regard to the cross-section of the hollow part, and when cleaning, if this cross-section is excessive, it is advisable to use a pipe with a diameter compatible with the appliance, making it run through the entire duct to the outside. - For better draught, it is advisable to use a double-walled metal pipe with a thermal insulating layer, thus avoiding condensation caused by cooling in the duct. Number of appliances per duct.

- Each duct can only be connected to a single device.

- The recommended minimum height is 4 to 5m. Please note that the upper end must always be above the highest part of the roof.

- Avoid installing ducts in close proximity to tall buildings. A distance of at least 8 meters should be taken into account.

- In the case of balconies or roofs with a slope of less than 15º, the duct must extend 1.20m above them.

- Avoid protections or “hats” that could hinder the draft. In the event of a large depression (excessive draft), install a damper inside and in an accessible location that allows it to be regulated.

Installation

- The diameter of the pipe must be neither smaller nor larger than the outlet of the device. If this is absolutely impossible, the reduction must be made as far as possible from the connection point.

- The duct that will be installed will run from the stove to the outside, being perfectly insulated and fixed to the wall.

- Do not rest the duct on the appliance.

- Carry it out in accordance with the advice already given here, and comply with local regulations if they exist. Comply with them so that mechanical cleaning and periodic maintenance operations can be carried out.

- The smoke duct must be made of materials resistant to high temperatures.

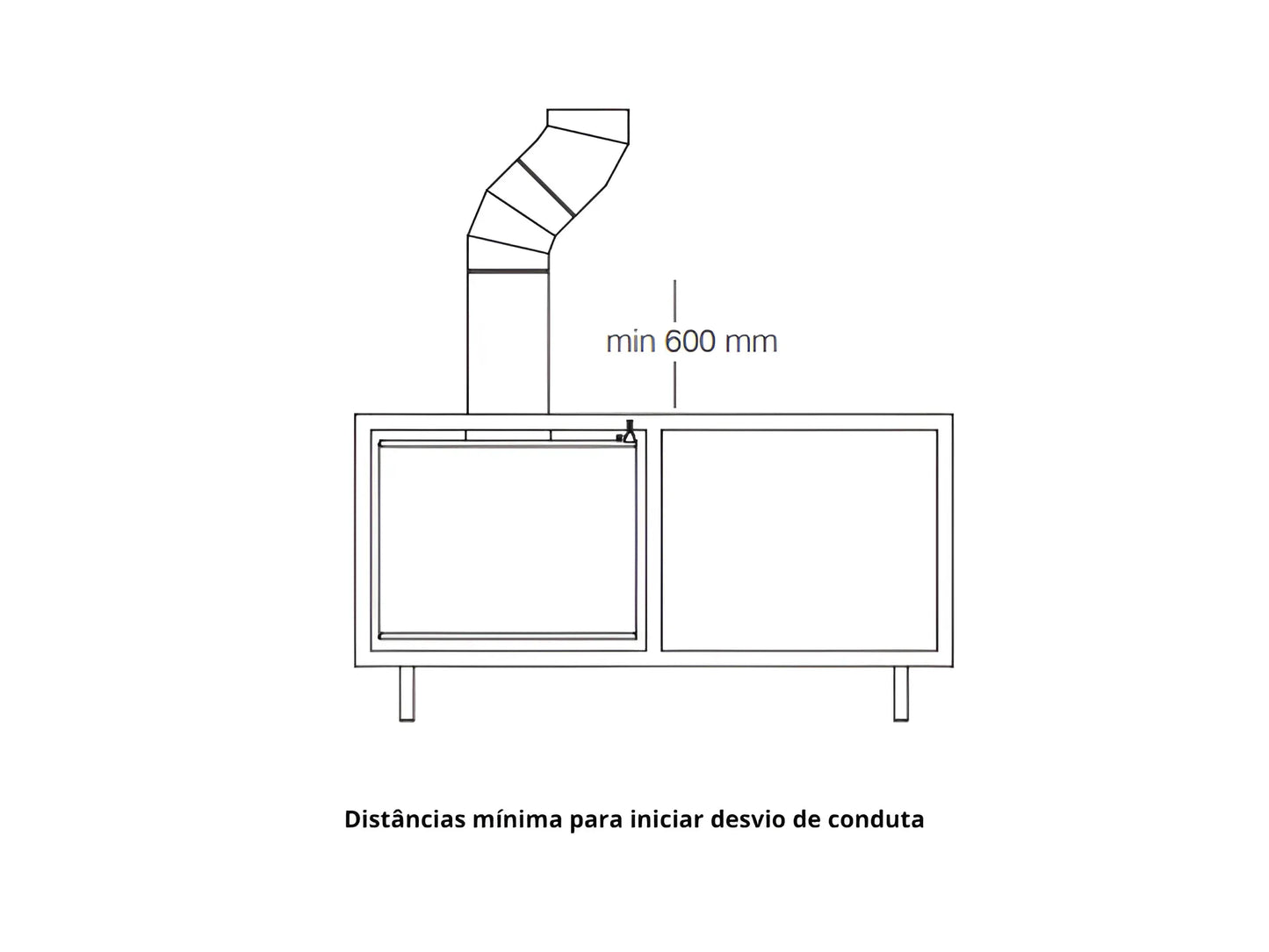

- The fitting can be done with a vertical pipe and (or) if necessary to divert the conduit, 45º bends should be used, and always at a fitting distance from the appliance greater than 600mm.

- All fittings or connections must be hermetically sealed to prevent smoke from escaping. If there is a mechanical ventilation system (MCV) in the location where the appliance is installed, the sealing of the smoke duct connections must be even more effective.

- The walls surrounding the stove and the flue must be made of fire-retardant materials and/or properly insulated with fibers or specific materials for high temperatures. The stove must be installed on a flat base, made of non-combustible materials.

When installing the appliance, all local regulations, including those relating to national and European standards, must be observed. The appliance must not be installed in shared chimneys.

Fuels

Use dense wood that has been cut two years previously and stored in a dry place. Dense wood gives off a large amount of heat and produces a good brazier (e.g. oak wood). Larger logs should be cut to a maximum length of 480 mm so that they can be used in the appliance's firebox. Avoid using green wood or wood with a high moisture content. This reduces the appliance's performance and makes the glass, internal panels and the flue more dirty. Wood from reclaimed wood, such as wood subjected to chemical treatments, agglomerated wood or wood from pallets, immediately makes the entire installation dirty, produces bad smells and hinders combustion. Green or salvaged wood, if used constantly, can cause deposits that can cause fires, especially in the flue.

Do not use:

- Coal

- Any and all types of liquid or gaseous fuel

Share