Wood Stove Remade Design Francisco Providência

Wood Stove Remade Design Francisco Providência

Couldn't load pickup availability

Eco-design wood-burning stove, designed by Francisco Providência. Made of cast iron, with a combustion chamber lined with expanded vermiculite panels to increase its energy efficiency. Available in 5 different supports.

- Power: 5.4kW (4.6kWmin.-7.9kWmax.)

- Firewood consumption: 1.5 kg/h

- Yield: 79% (min.71%-max.83%)

- CO rate (13%O2): 0.42%

- Smoking temperature: 224 ºC

- Smoke mass flow rate: 5.36 g/s

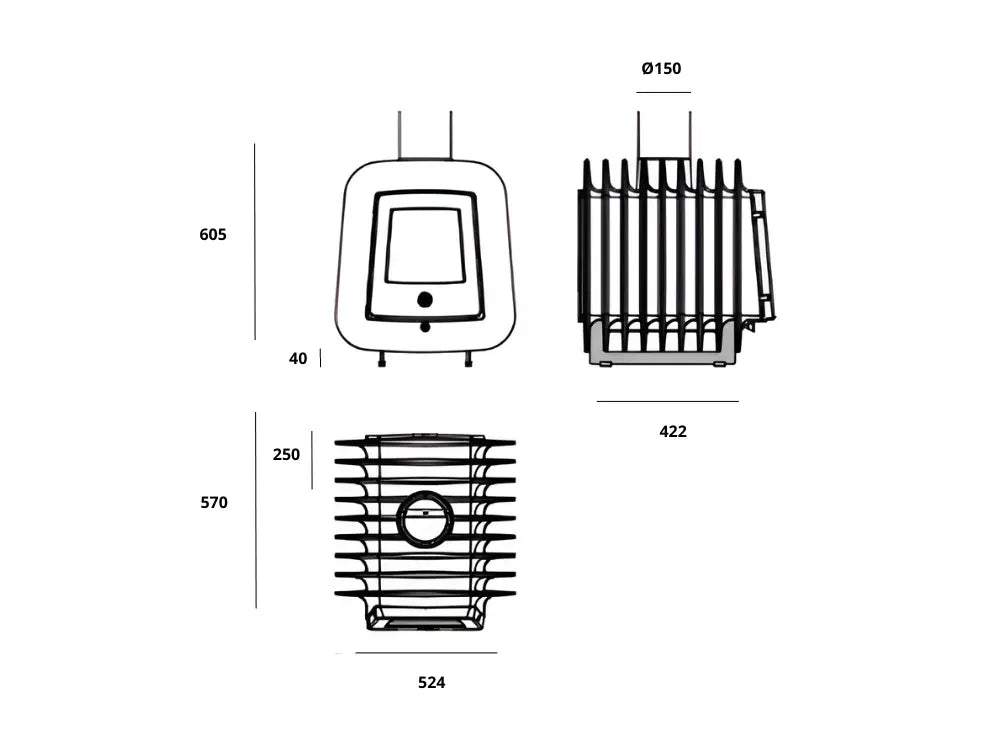

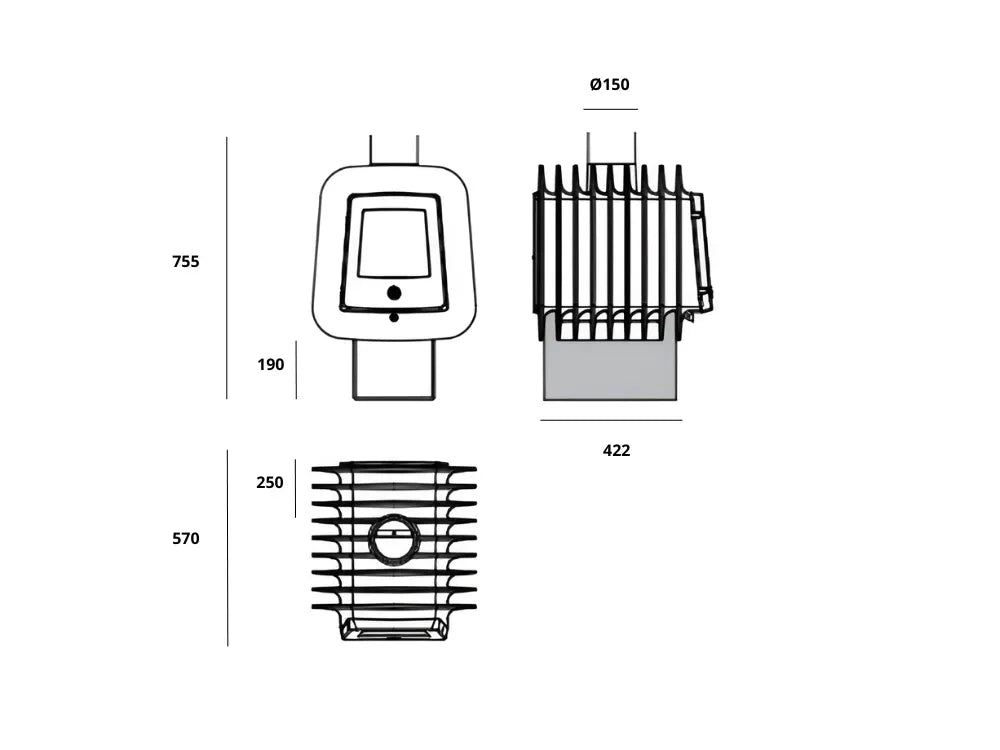

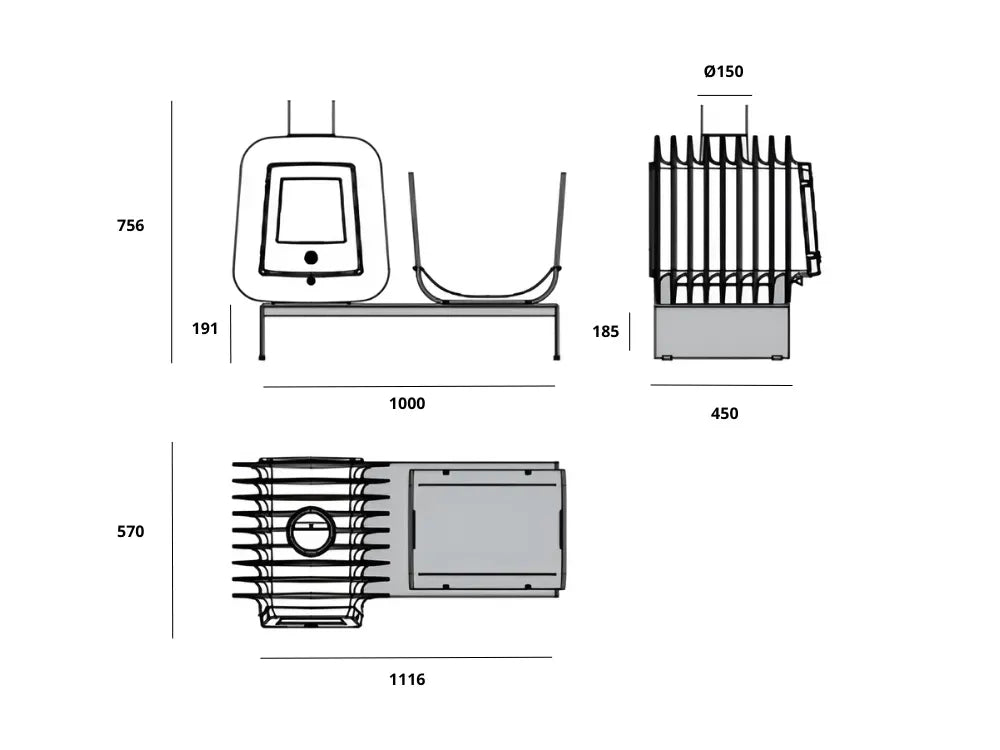

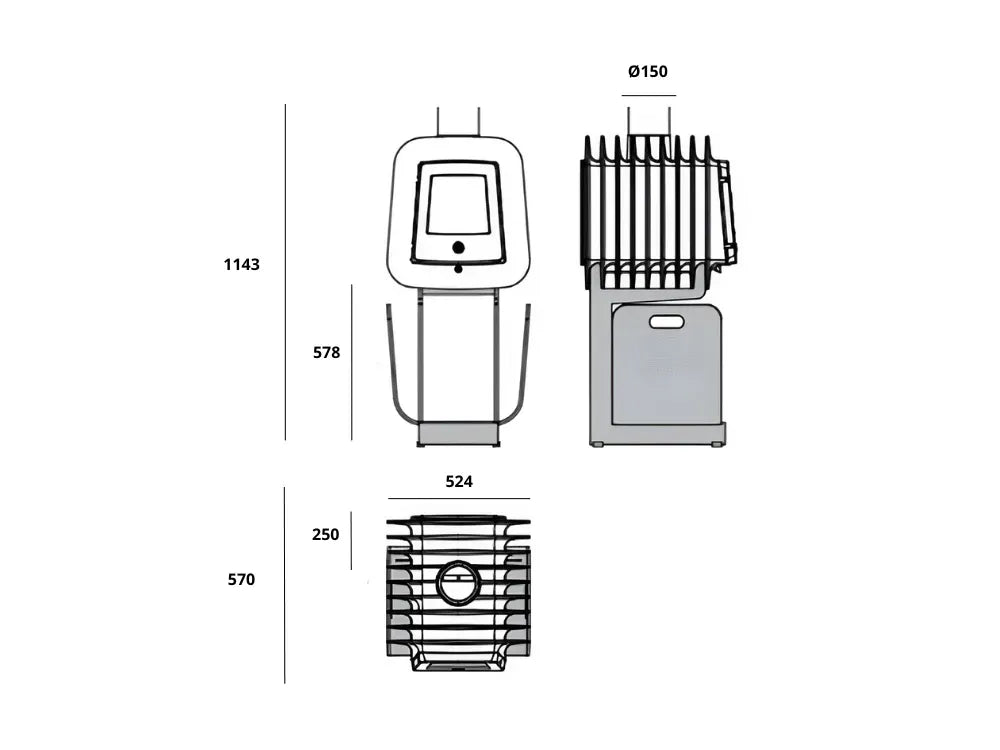

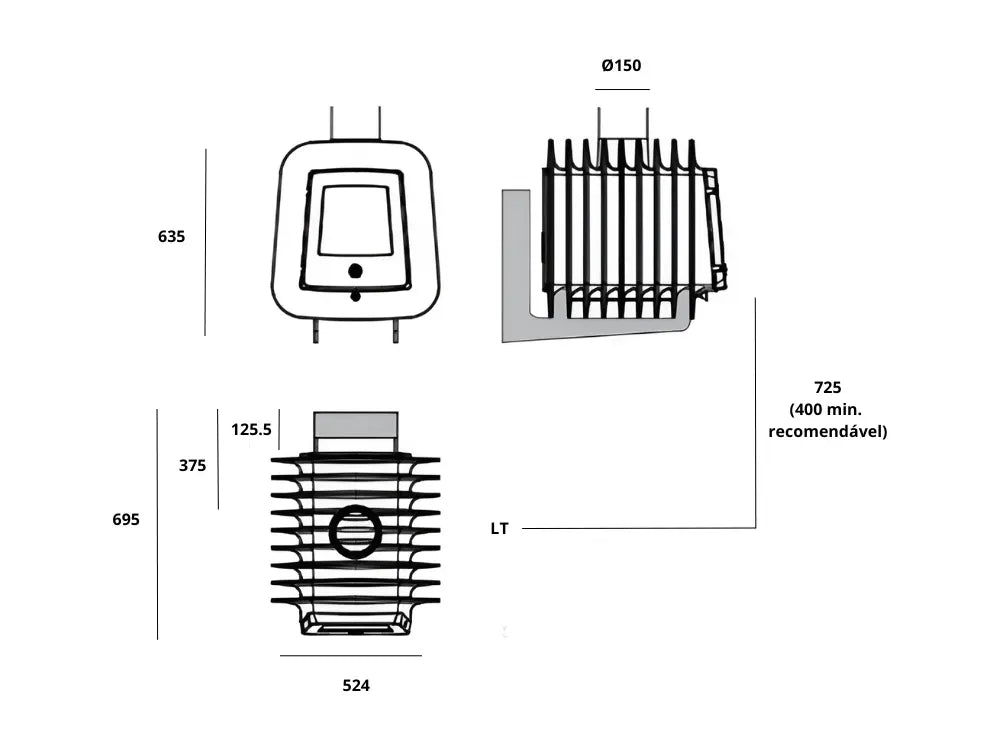

- Ø smoke outlet: 150 mm

- Time between recharges: 0.9 (h)

- Area to be heated: 70 m²

- Intermittent operation heating device

- Wood burning on a cast iron grate

- Side-opening front door, equipped with ceramic glass resistant to 750ºC

- Combustion air inlet register installed on the lower front of the body

- Obtained 70% from the reuse of cast iron scrap

- Stainless steel smoke deflector and discreet glass cleaning system

- Ash tray

- Painted in RAL 9005 or anthracite grey, resistant to high temperatures

- Various mounting accessories available

- Chimney diameter: Ø152.4 mm

- Combustion Chamber Dimensions (interior) (LxWxH): 278/234 x 460 x 280 mm

- Max. Firewood Dimension: 450 mm

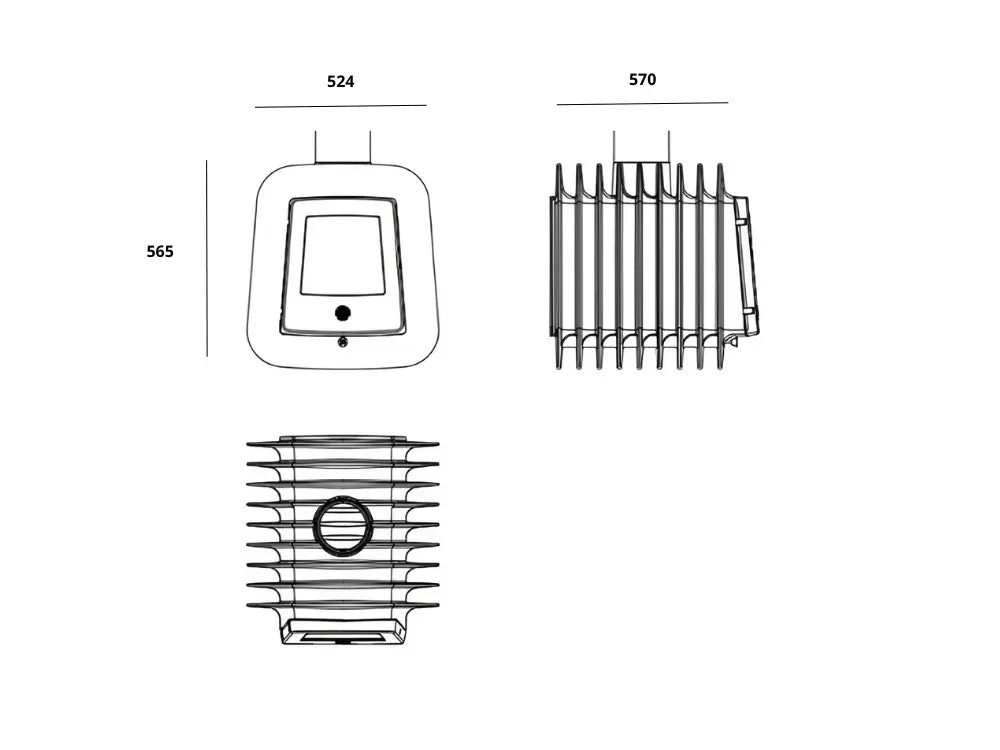

- Overall dimensions (LxWxH): 524 x 570 x 565 mm

Weights

Salamander: 199 kg

R1 Support: 3.6 kg

R2 Support: 18 kg

R3 Support: 45 Kg

R4 Support: 31 kg

R5 Support: 16 kg

Before Installation

- Check that the place where the stove is to be installed has a sufficient supply of oxygen. Wood combustion consumes oxygen. If the room where the stove is located is airtight or has a controlled ventilation system, clean air must be supplied from outside by installing an additional grille with a cross-section of no less than 50 cm².

- Make sure the support base is capable of supporting the total weight of the stove.

- Make sure that the materials surrounding the stove are not flammable (paper, plastic, wood, etc.).

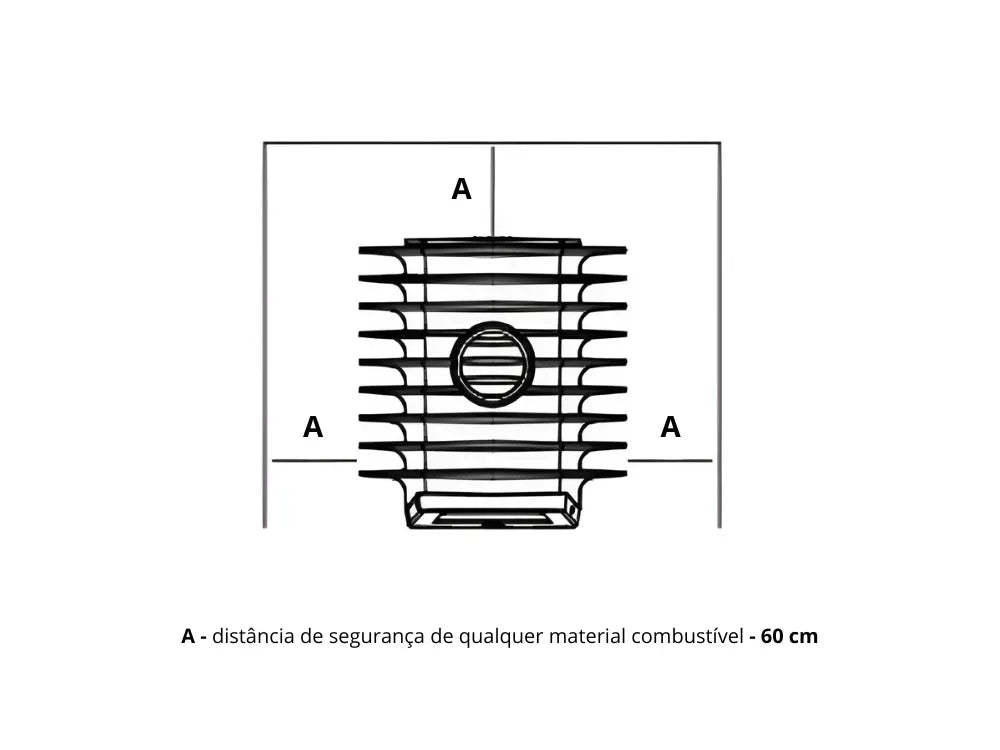

- We must take into account the safety distance of 60cm from any object that could deteriorate due to the effect of heat.

Smoke Duct

If it already exists:

- Check that the construction is in good condition and that when the device is in operation, there is a differential pressure of 12 Pa to ensure good draft.

- The duct must be compatible with the use, especially with regard to the cross-section of the hollow part, and when cleaning, if this cross-section is excessive, it is advisable to use a pipe with a diameter compatible with the appliance, making it run through the entire duct to the outside.

- For better draught, it is advisable to use a double-walled metal tube with a thermal insulating layer, thus avoiding condensation caused by cooling in the duct. Number of devices per duct.

- Each duct can only be connected to a single device.

- The recommended minimum height is 4 to 5m, bearing in mind that the upper end must always be above the highest part of the roof.

- Avoid installing pipes in very close proximity to tall buildings; a distance of at least 8 meters should be taken into account.

- In the case of balconies or roofs with a slope of less than 15º, the duct must extend 1.20m above them.

- Avoid protections or “hats” that could hinder the draft; in the event of a large depression (excessive draft), install a valve inside and in an accessible location that allows it to be regulated.

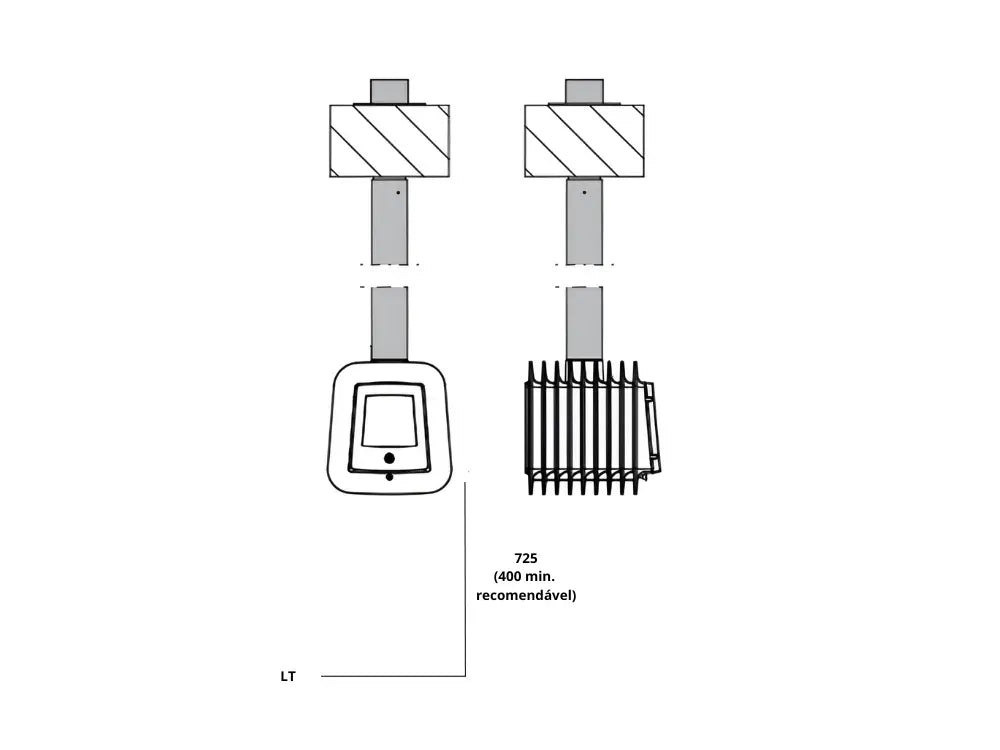

Installation

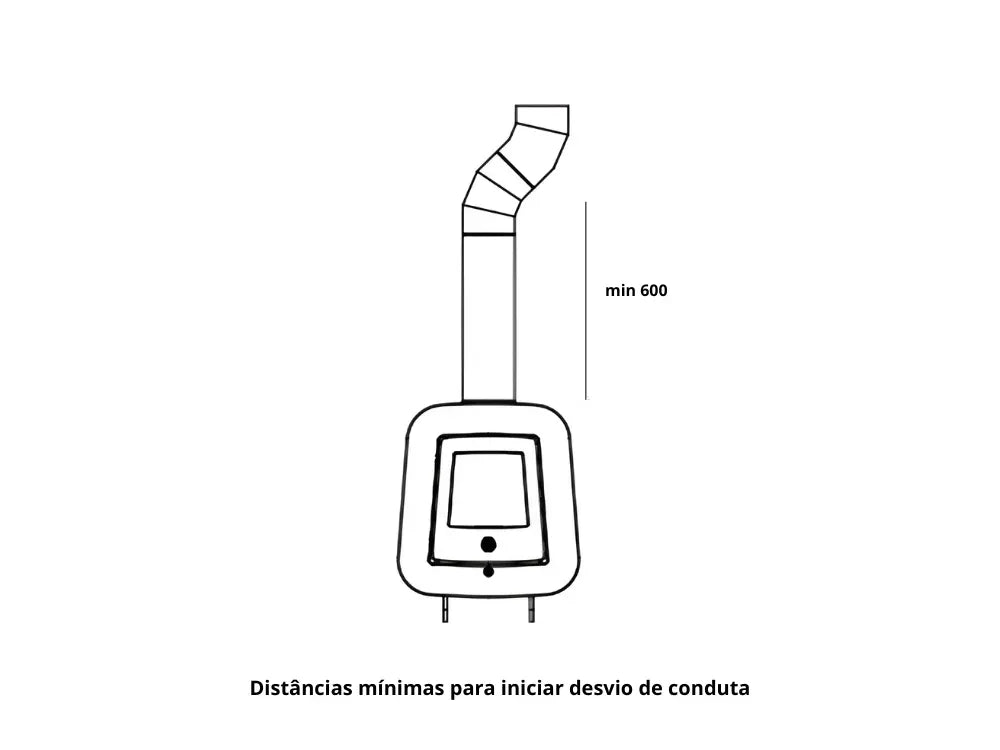

- The diameter of the pipe must be neither smaller nor larger than the outlet of the device. If this is absolutely impossible, the reduction must be made as far as possible from the connection point.

- The duct that will be installed will go from the stove to the outside, being perfectly insulated and fixed to the wall.

- Do not rest the duct on the appliance.

- Carry it out in accordance with the advice already stated here, and comply with local regulations if they exist, complying with them so that mechanical cleaning and periodic maintenance operations can be carried out.

- The smoke duct must be made of materials resistant to high temperatures.

- The fitting can be done with a vertical tube and (or) if necessary to divert the conduit, 45º bends should be used, and always at a fitting distance from the appliance greater than 600mm.

- All fittings or connections must be hermetically sealed to prevent smoke from escaping. If there is a mechanical ventilation system (MCV) in the location where the appliance is installed, the sealing of the smoke duct connections must be even more effective.

- The walls surrounding the stove and the flue must be made of fire-retardant materials and/or properly insulated with fibers or specific materials for high temperatures. The stove must be installed on a flat base, made of non-combustible materials.

- In the installation of the Salamander with supports no. 2 and 3, the space at the bottom of the same is not used for storing/packing firewood. The air inlet section (located at the bottom of the salamander) must be positioned so that it is not easily obstructed.

Fuels

Use dense wood that has been cut two years previously and stored in a dry place. Dense wood releases a large amount of heat and produces a good brazier (e.g. oak wood). Larger logs should be cut to a maximum length of 450 mm so that they can be used in the appliance's firebox. Avoid using green wood or wood with a high moisture content, as this reduces the appliance's performance and makes the glass, internal panels and the flue more dirty. Wood from reclaimed wood, such as wood subjected to chemical treatments, agglomerates or heavily used pallets, causes immediate dirt throughout the installation, produces bad smells and hinders combustion. Green or salvaged wood, if used constantly, can cause deposits that can cause fires, especially in the flue.

Do not use:

- Coal

- Any and all types of liquid or gaseous fuel

Share